Our goal is to drive change in the marketplace faster and further. Five years ago, a solar-powered, six-story office building in cloud-covered Seattle would have struck most people as not merely foolhardy but impossible. Today it exists.

– Denis Hayes, President, Bullitt Foundation

The idea for this article originated from an evening of watching “Xploration Nature Knows Best” from Steve Rotfield Productions. The episode, “Biobased Buildings” with host Danni Washington, encompassed a cohesive discussion on products and buildings that mimic nature—biomimicry in design. The show included two examples of biomimicry in design, StoColor® Lotusan® and the Bullitt Center.

StoColor® Lotusan® dates this publisher back to the Journal of Architectural Coatings, circa mid-2000s, when green building products were the ‘latest’ craze and were just starting to build momentum in the architectural coatings industry. There were low/no VOC coatings, white roof coatings, reflective exterior coatings, among others. But one coating, StoColor® Lotusan®, was a category in its own right.

StoColor® Lotusan® is a great example of biomimicry in building material design as the coating mimics a lotus leaf by repelling dirt and water from façade walls. According to Sto Corp’s brochure for StoColor® Lotusan® “Dirt particles are unable to obtain a hold on the leaves of the lotus plant and simply flow off with the rain droplets that fall on the plant. The StoColor Lotusan exterior coating possesses a highly water-repellent surface similar to that of the lotus leaf. Its microstructure has been modeled on the lotus plant to minimize the contact area for water and dirt. The surface additionally offers enhanced hydrophobic properties.”[1]

The Bullitt Center was also featured in the bio-based building episode. The Bullitt Center design was inspired by a Douglas fir forest—utilizing the trees’ characteristics in key design elements of the building such as energy and water. Its photovoltaic (PV) array was built like a tree canopy, capturing more energy than the building actually uses in the summer time. In addition, the building soaks up rain water, stores it and uses the water. All waste in the building is composted.

As stated in the Message from Denis Hayes states on their website “Arguably, our chief innovation is that we brought all these ideas together in one place at the same time. The Bullitt Center—instead of pursuing just net zero energy, net zero water, net zero carbon, composting toilets, toxic-free materials, an enticing stairway, 80+ percent day lighting using high-performance windows—chose all-of-the-above. And we chose them for a six-story urban infill project in a dense neighborhood in one of the greatest cities in the world, Seattle.”

So then what is biomimicry? According to the Biomimicry Global Design Challenge website http://challenge.biomimicry.org “Biomimicry is an approach to innovation that seeks sustainable solutions to human challenges by emulating nature’s time-tested strategies.” The Biomimicry Global Design Challenge is hosted by the Biomimicry Institute.

The Biomimicry Institute was created in 2006 by Janine Benyus and Bryony Schwan “to share nature’s design lessons with the people who design and make our world.” The Biomimicry Institute describes its mission as an ongoing process, “Our goal today is for biomimicry to become a natural part of the design process. We accomplish this by tackling one massive sustainability problem at a time through our Design Challenges platform, mobilizing tens of thousands of practitioners with the support of the Global Biomimicry Network to solve the challenge, and then providing those practitioners with AskNature as a tool to begin the solution process.”

Although biomimicry in design can be seen throughout our history, Denis Hayes, the president of the Bullitt Foundation, explains in his article “Cities are the Greatest Hope for our Planet” that the movement of biomimicry did not really come into fruition until 1997 when Janine Benyus, the cofounder of the Biomimicry Institute, published Biomimicry: Innovation Inspired by Nature. [2]

The following information was kindly provided to PRISM by the Bullitt Center. The proceeding case study from Vitro Architectural Glass, examines the use of Solarban® 60 Glass and Starphire Ultra-Clear™ Glass in the curtainwall of the Bullitt Center designed by Schüco USA and fabricated by Goldfinch Brothers.

[1] “StoColor® Lotusan®”, Sto Corp. http://www.stocorp.com/coatings-us/#lotusan. (Accessed 5/26/17)

[2] Denis Hayes. “Cities are the Greatest Hope for our Planet”, Ensia, https://ensia.com/voices/cities-are-the-greatest-hope-for-our-planet. (October 28, 2014)

The Bullitt Center

Buildings account for an estimated 39% of carbon dioxide emissions, 65% of waste and 70% of electrical use in the United States. In the Pacific Northwest, a changing climate is already shifting our use of water, energy and other natural resources. To address this reality, the Bullitt Center in Seattle, WA is demonstrating what is possible today and inspiring tomorrow’s leaders to go even farther.

As the first urban structure of its kind, the Bullitt Center is inherently changing the way we think about buildings. Serving as a highly visible example of what’s possible when a team of people come together to advance uncommon wisdom, the Bullitt Center has accomplished the following:

- Living Building: The 6-story, 50,000 sq. ft. building is the nation’s first urban mid-rise commercial project to achieve the rigorous goals of the Living Building Challenge, the most ambitious benchmark of sustainability in the built environment.

- Net Positive Energy: In 2016 from the solar panels on its roof, the Bullitt Center produced 28 percent more energy than it used. Achieving net positive energy for a commercial office building in cloudy Seattle is a stunning accomplishment, due in large part to tenants in the fully leased building embracing the project mission.

- Award Winning: The Bullitt Center has won a wide array of awards, including World Architecture News “Sustainable Building of the Year,” Engineering News-Record “National Best Green Project,” and Sustainable Building Industry Council “Beyond Green” award.

- Influential: With a high profile, the Bullitt Center has influenced many other construction projects, including the Obama Library in Chicago and the Living Building at Georgia Tech.

SOLAR

To achieve “net zero energy,” the Bullitt Center generates as much electricity as the building requires in a year from its rooftop solar power system. During eight months of the year – primarily the sunny summer months – the photovoltaic (PV) array produces more electricity than building occupants use; in four gray winter months, it produces less.

To maximize the solar roof’s output in Seattle, Bullitt chose SunPower panels because they were the highest efficiency commercially available solar panels in the world, delivering up to 50 percent more energy than conventional panels, even on cloudy days. About 20 percent of the sunlight that strikes the surface of each module is converted directly into electricity. These solar panels have no moving parts to break or wear out and are guaranteed for 25 years.

570 photovoltaic panels cover the Bullitt Center roof, each with a rated capacity of 425 watts, meaning the total array will generate 242,000 watts (242 kilowatts) of power at noon on a sunny day. From analysis of the actual sunlight expected to hit the panels (including dim sunlight on cloudy days), it is estimated that the solar roof will generate approximately 230,000 kilowatt-hours (KWH) of energy in an average year.

In order to maximize solar exposure, the roof of the Bullitt Center looks like the flat mortar boards worn at graduation ceremonies. A steel and aluminum racking system allows the panels to extend beyond the walls of the building and was designed with flexibility in mind.

As part of the Living Building Challenge, the Bullitt Center meters its energy production and consumption on a continuous basis, showing the results in the lobby and on the website (http://www.bullittcenter.org/dashboard/). To be certified as a Living Building, the Bullitt Center had to produce as much energy as it used over a period of 365 consecutive days – a goal they accomplished in April 2014.

Tenants are allocated an energy budget based on the percent of the building they occupy. Tenants that remain within their budget are provided with a rebate for the full cost of their electricity at the end of each year.

Solar energy produces no greenhouse gases, no bomb grade materials, and no radioactive waste. It involves no mountain-top removal or fracking. Solar energy does not acidify the world’s oceans or produce urban smog. Instead of posing additional hazards during natural disasters, solar energy offers resilience. A huge solar spill is called “a nice day.”

Each PV panel generates approximately 1100-Watt hours of energy a day. This is enough to:

• Power 7 lights for 8 hours a day (20 W fluorescents, equivalent to a 100 W incandescent lamp).

• Charge 115 iPhones (iPhone 5, full charge from zero to 100%)

• Brew 16 cups of coffee (12 oz. drip)

WATER

Seattle receives less yearly precipitation than Atlanta, Boston, Houston or New York. And even in arid cities, rain typically falls in short, intense bursts that can carry pollutants down storm drains into local rivers, lakes and bays. Like all cities, Seattle is full of hard, impermeable surfaces, so it’s difficult for rainwater to find its way back into the ground, streams and rivers without picking up oils and pollutants along the way. In Seattle, large rain events quickly overwhelm their combined storm and waste water system, resulting in the discharge of untreated sewage into the Puget Sound.

If every building could capture, store and make productive use of the rain that falls on it, and return what’s been used to the hydrosphere in an undiminished state, one would be less reliant on remote water sources, demand for expensive waste treatment systems would be lowered, and the health of waterways would be improved.

Clean rainwater falling on the Bullitt Center’s roof through gaps between the PV array is carried by downspouts to a 52,000-gallon cistern, an 8-foot tall, 950 square-foot room in the basement. The system supplies all non-potable fixtures in the building including toilets, hose spigots, and irrigation systems.

In addition, the system has been designed and constructed to meet all potable water needs for the building once it is fully permitted. Rainwater will pass through a series of filters to remove impurities, an ultra-filter that is so fine that it takes out viruses, and an ultraviolet disinfection system. Until approved, the system will be regularly tested and monitored, and potable water will come from the city’s water supply system.

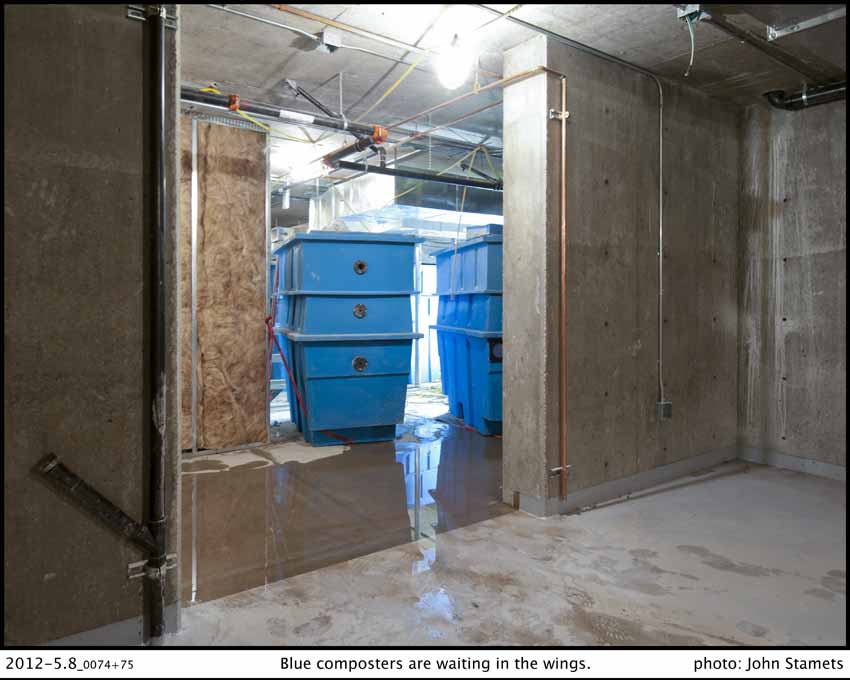

Water for toilet flushing is nearly eliminated in the building by composting human “waste” on-site using 10 large composting units in the building’s basement. Foam flush toilets using less than a cup of water and natural soap convey solids and liquids through piping to the basement. Wood chips are added to the composting units as an additional carbon source, and to help manage moisture levels. The compost is rotated about once a week and air is circulated through the composters to help accelerate the composting process. Temperatures maintained in the range of 135°F to 165°F ensure all pathogens and contaminants are sterilized or killed. The resulting compost, along with nutrient-rich leachate drained from the composters, will be taken to a nearby facility to be incorporated with other composted material and used as a soil amendment.

MARKET TRANSFORMATION

Local Green Economy

A curtain wall (window) system engineered by the German company, Schüco, met the high-performance needs of the Bullitt Center design, but the product was only available in Europe. In a remarkable example of creating real change, a partnership was established between Schüco and Goldfinch Brothers, a family-owned company based in Everett, WA. Goldfinch Brothers developed a licensing agreement with Schüco to fabricate, distribute, and install Schüco products in the US. Goldfinch Brothers sent a team to Germany to learn the fabrication process, and now the Schüco-engineered curtain wall systems are fabricated and assembled by Goldfinch Brothers in their Everett facility. These high-performance curtain wall systems are now available for future projects in North America, providing high-performance windows for US buildings and raising the bar on domestic manufacturers to compete in this market.

Heavy Timber Construction

The Bullitt Center aims at creating regional design vernacular, one that is informed by the culture and tuned to the conditions of the environment. A building in Phoenix should be distinct from one in Seattle because it is responding to a very different environmental context and building culture.

This philosophy guided the design team towards selecting wood as the building’s primary structure, given the abundance of forest resources available in the Pacific Northwest, the tradition of wood as building material in this region, and because of the many environmental benefits of using wood. Wood is locally available and can be harvested from responsibly managed forests, making it a good environmental choice. The carbon sequestered in this building will stay out of the atmosphere for as long as the structure is intact, at least 250 years.

Many heavy timber buildings of this scale in downtown Seattle have lasted through fires, earthquakes, and well over 100 years of use. This building updates the enduring tradition of these buildings with the benefit of modern engineering, a sturdy concrete base, and an engineered timber frame made from sustainably grown and harvested wood rather than old-growth trees.

Forest Stewardship Council™

100% of the wood in the Bullitt Center comes from forests certified to standards set by the Forest Stewardship Council (FSC). In addition, the Bullitt Center is the only commercial building in the U.S. to earn the Forest Stewardship Council Project Certification, in recognition of responsible forest products use throughout the building.

FSC is an independent nonprofit organization that sets rigorous standards under which forests are certified to ensure they are responsibly managed. Endorsed by groups such as Greenpeace, World Wildlife Fund, the Sierra Club and the National Wildlife Federation, FSC is considered the gold standard in forest certification.

In the U.S. and Canada, there are more than 170 million acres of forestland and nearly 4,500 “chain-of-custody” companies certified to FSC standards. FSC’s chain-of-custody standards ensure that FSC-certified wood products are tracked from the forest to the end user, such as the Bullitt Center.

For the Bullitt Center, Matheus Lumber in Woodinville, WA was the FSC-certified lumberyard that sourced wood products for construction.

PROJECT TEAM

• Owner: Bullitt Foundation bullitt.org

• Developer: Point32 point32.com

• Architect: The Miller Hull Partnership millerhull.com

• General Contractor: Schuchart schuchart.com

• Mechanical and Electrical Engineers: PAE Consulting Engineers pae-engineers.com

• Structural Engineers: DCI Engineers dci-engineers.com

• Building Envelope Consultant: RDH Building Envelope Consultants rdhbe.com

• Water System Engineer: 2020 Engineering 2020engineering.com

• Energy Consultant: Solar Design Associates, Inc. solardesign.com

• Civil Engineers: Springline Design

• Landscape Architect: Berger Partnership bergerpartnership.com

• Lighting Consultants: Center for Integrated Design College of Built Environments, University of Washington cidseattle.com/idl

• Shoring Design: CT Engineering Inc. ctengineering.com

• Surveyor: Bush, Roed & Hitchings, Inc. brhinc.com

• Geotechnical Engineer: Terracon terracon.com

• Building Manager: Unico Properties unicoprop.com

The Bullitt Center, regarded by many as the world’s greenest commercial office building, was constructed with Solarban 60 solar control, low-e glass and Starphire ultra-clear glass by Vitro Glass. Photos © 2014 Tom Kessler. All Rights Reserved.

VITRO ARCHITECTURAL GLASS

Solarban® 60 Glass and Starphire Ultra-Clear™ Glass used on the Bullitt Center4

• Owner: Bullitt Foundation

• Architect/Designers: The Miller Hull Partnership LLP

• Vitro Architectural Glass Products: Solarban® 60 Glass and Starphire Ultra-Clear™ Glass

• Curtain Wall Designer: Schüco USA, Newington, Conn.

• Glazing Contractor/Curtain Wall Fabricator: Goldfinch Brothers, Everett, Wash.

• Glass Fabricator: Northwestern Industries, Inc., Seattle

Project Background

The Bullitt Center, regarded by many as the world’s greenest commercial office building, was designed by The Miller Hull Partnership to demonstrate how buildings can function as completely integrated, self-sustaining, living organisms.

In developing the six-story glass and metal mid-rise, lead design architect Brian Court and building performance specialist Jim Hanford specified hundreds of sustainable building products and implemented dozens of design strategies. They enable the Bullitt Center to execute its core performance functions while generating or renewing, on-site, 100 percent of its energy, water and waste management functions.

The signature design element of the six-story Bullitt Center in Seattle is the “irresistible stairway,” featuring Starphire glass by Vitro Glass, providing panoramic views of Seattle and Puget Sound. Photos © 2014 Tom Kessler. All Rights Reserved.

Hanford said the fenestration system was critical to enabling the Center to attain its ambitious energy and environmental performance goals. As part of a sophisticated curtain wall assembly designed by Schüco USA and fabricated by Goldfinch Brothers, the system incorporates triple-glazed insulating glass units (IGUs) framed in aluminum and glazed with two lites of Solarban 60 solar control, low-e glass by Vitro Architectural Glass to provide window system U-values as low as 0.17.

“We specified Solarban 60 [glass] because it provided the best balance of thermal performance, solar control and daylighting performance to meet the needs of the project,” Hanford explained. “To allow daylighting deep into the floor plate, we knew we would need large glass areas with high visible light transmittance. To offset the heating load penalty of the large glass areas, we wanted to get the lowest possible heat loss rate, and that meant using a product such as Solarban 60 glass with argon fill in the insulating glass units.

“Because we have a long history of using Solarban 60 [glass] on other projects, we knew we would be comfortable with how it looked on the building,” he added.

In addition to the large windows, Solarban 60 glass was used to fabricate the entrance and interior doors and operable skylights, which were reinforced with a translucent laminated interior lite. The fenestration system, together with the high ceilings, enables the Bullitt Center to draw more than 80 percent of its lighting needs from the sun. The curtain wall also is equipped with manual and motor-controlled openings to facilitate passive cooling and natural ventilation, along with retractable external blinds to help block solar heat.

Another Vitro Glass product, Starphire Ultra-Clear glass, is integral to the building’s signature design element, an irresistible stairway that entices occupants to climb steps instead of riding the elevator by furnishing panoramic views of downtown Seattle and Puget Sound. With visible light transmittance (VLT) of at least 90 percent, in thicknesses ranging from 3 to 19 millimeters, Starphire glass is the industry’s most transparent architectural glass.

For more information about Solarban 60 glass, Starphire glass and other Cradle to Cradle Certified™ architectural glass products by Vitro Glass, visit www.vitroglazings.com, or call 1-855-VTRO-GLS (887-6457).

© 2014 Vitro Architectural Glass. All rights reserved. Starphire Ultra-Clear is a trademark and Solarban and Starphire are registered trademarks owned by Vitro.

The PPG Logo is a registered trademark of PPG Industries Ohio, Inc.

Cradle to Cradle Certified is a trademark licensed by the Cradle to Cradle Product Innovation Institute.