Aluminum panels from Lorin ensure durability of the decorative and functional metal building exterior

Recently the City of Austin, Texas built a new central library building, designed by architects Lake Flato Architects and Shepley Bulfinch. The architects chose perforated anodized aluminum from Lorin Industries, Inc. to serve as a central façade design element. The new Austin Central Library building, opened to the public in October 2017, makes full use of the functional and aesthetic benefits of perforated anodized aluminum panels, providing shade for the building and its entrances. A large panel incorporates literary quotations which are visible on the building’s floor. The panels add to the overall building aesthetic as light shines through the metal.

Austin Central Library project background

The new Austin Central Library is a 200,000-square-foot building serving the entire community of Austin, Texas. Photo courtesy of Lorin Industries, Inc.

The new Austin Central Library is a 200,000-square-foot building serving the entire community of Austin, Texas. Lake Flato Architects and Shepley Bulfinch designed the library to be a gathering place for all of the citizens of Austin, with a large six-story atrium serving as “the new living room for Austin,” as described by Jonathan Smith of Lake Flato Architects. Around the edges of the atrium there are a variety of spaces designed for different kinds of activities including public computers, shared learning rooms, co-working spaces and more.

The rest of the building features a number of other dedicated spaces: a traditional quiet reading room, half of an entire floor of the six-story building dedicated to children and teens, and plenty of space for books and other lendable materials. On top of the 6th floor roof is a rooftop outdoor reading garden, with a live shade oak tree.

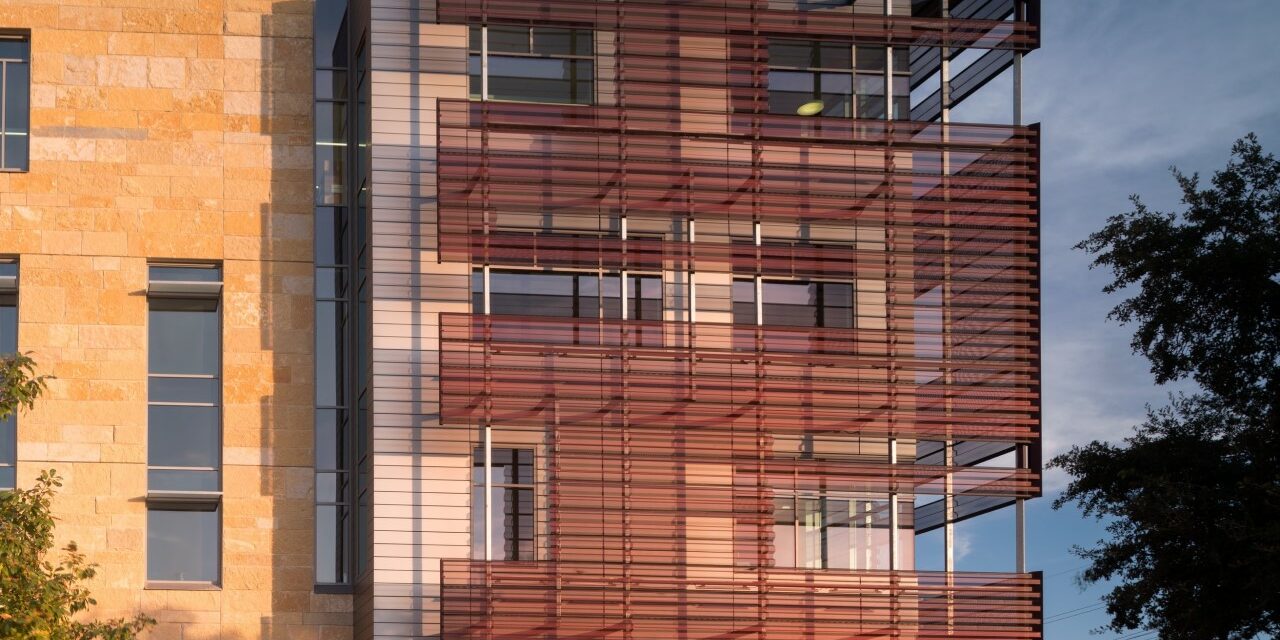

The library building is situated on a site that functions as a gateway to downtown Austin, Smith explained, and so the exterior of the building was designed to suit the site itself and to be in conversation with surrounding buildings, including the City Hall building just four blocks away. Much of the building façade is constructed with local limestone and on the South side, cantilevering off the building, is a metal façade component that serves as a set of large screened-in porches overlooking the nearby lake.

Perforated anodized aluminum as a central design element

Early on architects knew they wanted a unique exterior for the building. They wanted to use aluminum for its low weight and high recycled content as the building is on track for LEED Platinum certification. In particular, the architects wanted corrugated perforated aluminum with a deeper and more three-dimensional look for the screened porch section of the building exterior, and chose anodized aluminum over coatings for this reason.

The search for such a material led them to Lorin Industries Inc., a global industry leader in continuous coil anodizing of aluminum. Lorin’s unique aluminum anodizing process not only provides the kind of textured, three-dimensional appearance that the architects were searching for, but also protects the metal from corrosion, ensuring durability and a long lifespan.

The architects worked with Lorin experts to produce and compare samples of different colored aluminum panels alongside the local limestone that would form the other portion of the building exterior.

With these samples and a larger mockup, the teams worked together to finalize the color and finally to produce the panels, framing and closures for the corrugated perforated aluminum exterior. The panels feature different levels of perforation based on where they are located, with different patterns or percentages of the metal open to provide more shade or greater visibility. Panels of the Lorin anodized aluminum fold off the façade and become the entry canopies over the three main entries of the building, providing shade and a unified exterior appearance.

Photo credit: Nic Lehoux, courtesy of Lorin Industries, Inc.

Benefits of perforated anodized aluminum

The perforated anodized aluminum provided the Austin Central Library project with the exact mixture of unique aesthetics and functionality that the architects sought in designing the building. The light weight attribute of the panels was important in the structural design of the building, as its simpler connections helped reduce costs. Additionally, the durability of Lorin anodized aluminum will preserve both the aesthetic and practical functions of the metal panels throughout the life of the building.

Typically, perforated anodized aluminum is created by punching or stamping a specific hole pattern onto the metal, either in a continuous coil form or by sheet. The coil or sheet is fed through a computer-controlled punch press, which is designed to efficiently and quickly perforate a variety of patterns onto the metal. After the metal is perforated, it is anodized to provide the unique electrochemical protection, including inside of the holes.

Once the design is complete and the perforated panels have been produced, the installation process starts by installing the framing. Once the framing is complete, the installer can then install the panels according to the details and guidelines on the perforator’s supplied architectural shop drawings. Perforated panels are usually one of the last elements to be installed on a building. With perforated anodized aluminum in particular, most panels are light enough to install without a crane. This reduces installations costs and is one of the reasons why aluminum is so highly favored for perforated metals building projects like the Austin library.

This ease of installation as well as the durability, sustainability and aesthetics attributes of Lorin perforated anodized aluminum, made it ideally suited for use on the Austin Central Library.

About the author

Phil Pearce, Vice President of Global Sales and Marketing, Lorin Industries, Inc.

Phil Pearce, Vice President of Global Sales and Marketing, Lorin Industries, Inc.

With over 37 years of sales and marketing experience, 25 of which he spent focused on the architectural industry, Phil Pearce is the Vice President of Global Sales and Marketing for Lorin Industries, Inc. In this role, Pearce oversees strategic domestic and international sales and marketing for Lorin.

Pearce brings decades of expertise to his work in customer relationship management, market development, project solutions, and product development. Additionally, Pearce oversees the work of a number of teams within Lorin Industries, including sales, distribution, marketing, and customer care. Pearce’s architectural industry and sales expertise contribute greatly to Lorin’s success and customers’ satisfaction.

Lorin Industries, Inc.

Lorin Industries, Inc. has provided coil anodized aluminum to markets worldwide for over 60 years. Our history of global leadership in anodized aluminum finishing for architectural markets began with bringing the process to market in 1953, and continues today with industry leading innovation. Lorin has worked with some of the world’s foremost architects, designers, and fabricators to create new and exciting building designs that last throughout generations.

Whether used for exterior wall cladding systems, roofing systems, sunscreens, interior panels, or decorative interior applications, the possibilities for coil anodized aluminum are infinite. The natural beauty of Lorin’s anodized aluminum finishes brings newly constructed and renovated buildings to life, while providing a strong durable surface that will never chip, flake, or peel. Additionally, Lorin’s coil anodized aluminum products have been used for automotive, transportation, consumer appliances, and any number of other industries, with the same excellent aesthetics and durability long proven in architectural applications. At Lorin, we can help you reflect your vision with Lorin anodized aluminum.

For additional information visit www.lorin.com and follow Lorin on Twitter, Facebook, and LinkedIn.