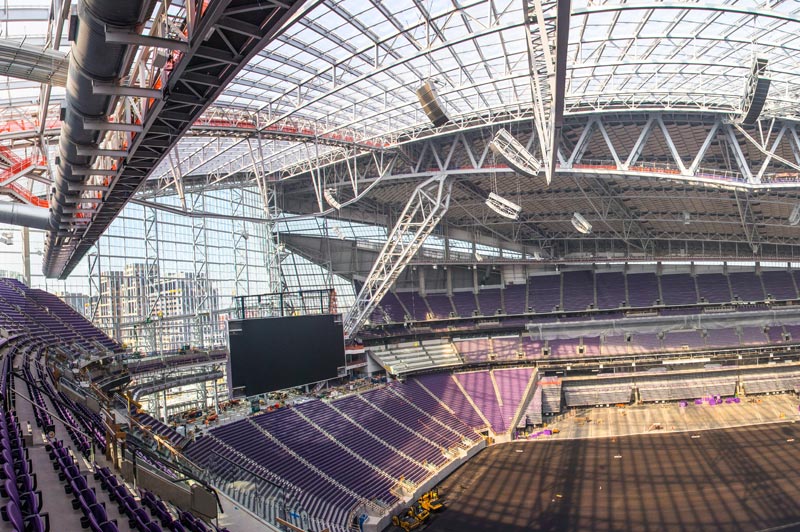

The new home of the Minnesota Vikings, U.S. Bank Stadium, will become the first sports facility in the United States with a transparent roof, permitting outdoor light without weather restrictions. Utilizing material from the franchise’s Official Science Partner, 3M, the venue will be covered by high-performance film, extruded from 3M Dyneon Fluoroplastic ETFE (ethylene-tetrafluoroethylene). The product, which lets light in, is lighter than glass, and more cost-effective than retractable alternatives.

Open-air football stadiums are not often a viable option in northern climates. The Dallas-based firm HKS Architects designed the stadium roof using ETFE film cushion technology, which is already widespread in Europe and Asia, to enable year-round use for a variety of events. The design lowered construction costs by around $100 million compared to a retractable roof.

Rendering of U.S. Bank Stadium interior showing 3M signage. Image courtesy Minnesota Vikings

“3M is a company that is synonymous with science and innovation in the minds of millions of people around the world,” said Vikings Owner/President Mark Wilf. “We are thrilled to work with a Minnesota-based global innovator like 3M to enhance the game day experience for Vikings fans.”

The partnership is a 10-year deal that allows 3M and the Vikings to work together on specific creative media projects, provides branded signage inside U.S. Bank Stadium – including a permanent sign in the Northeast corner of the stadium measuring more than 4,800 square feet – and makes 3M the preferred supplier of branded first aid stations in the stadium.

“We’re proud to partner with the Minnesota Vikings to help bring the story of 3M science to an even broader audience,” said Don Branch, vice president and chief marketing officer for 3M. “We can apply our science in so many ways to help provide customer solutions. More than 50 3M products have gone into the design and build of this architectural marvel – U.S. Bank Stadium.”

Vikings fans will see 3M technology nearly everywhere they look inside the stadium – from the graphic films and DI-NOC Architectural finishes in concessions, to the Fluoroplastic ETFE on the clear, lightweight and self-cleaning roof constructed by Vector Foiltec with film manufactured from 3M Dyneon Fluoroplastic ETFE by NOWOFOL Kunststoffprodukte GmbH. Even during construction, 3M technology helped builders stay safe through personal safety products like eye wear, helmets and hearing protection. 3M fire barrier products will also protect the stadium for years to come. For more information on the ETFE roof, you can read about it here.

Energy Efficient Insulating Air Cushions Lower Operating Costs

The stadium’s 248,000-square-foot roof and facade is covered by 75 three-layer ETFE film cushions, making U.S. Bank Stadium the largest ETFE film project in the United States. Some of the individually air-filled cushions are more than 1,200 square feet long and about 32 feet wide. The top film is printed with a geometric pattern, which scatters the sunlight and prevents a greenhouse effect in summer. In winter, the film roof protects the interior from the cold outside temperatures.

U.S. Bank Stadium and the ETFE roof made with 3M fluoropolymer. Photo courtesy Minnesota Vikings

The film cushions allow 95 percent of daylight to pass through, but their weight is only about five percent of the weight of glass. As a result, the supporting steel structure is light and slender, offering spectators a premium view of the playing field.

Designed for High Snow Loads

Since the Metrodome’s roof collapsed in 2010 under the weight of a 17-inch snowstorm, architects and roof planners paid particular attention to the load-bearing capability under heavy snow falls. Compared to other roofing membranes, ETFE films feature superior values for tear strength, resistance to tear propagation and puncture resistance – which let the air-filled cushions easily cope with highly concentrated impact loads like hail. Their use in northern Europe and the Alps prove their winter compatibility in areas with heavy snow fall.

U.S. Bank’s asymmetric roof inclines more toward the north to fend off the snow. The films are so smooth snow can hardly get a grip, sliding off in an almost controlled manner. A heavy rain shower is enough to clean it.

To learn more about Fluoroplastic ETFE, you can read about it here.

About 3M

At 3M, we apply science in collaborative ways to improve lives daily. With $30 billion in sales, our 90,000 employees connect with customers all around the world. Learn more about 3M’s creative solutions to the world’s problems at www.3M.com or on Twitter @3M or @3MNewsroom.

3M and Dyneon are a trademark of 3M Company.