WHAT IS PASSIVE HOUSE?

Passive House design is a comprehensive systems approach to building modeling, design, and construction that produces extremely resilient, energy-efficient buildings.

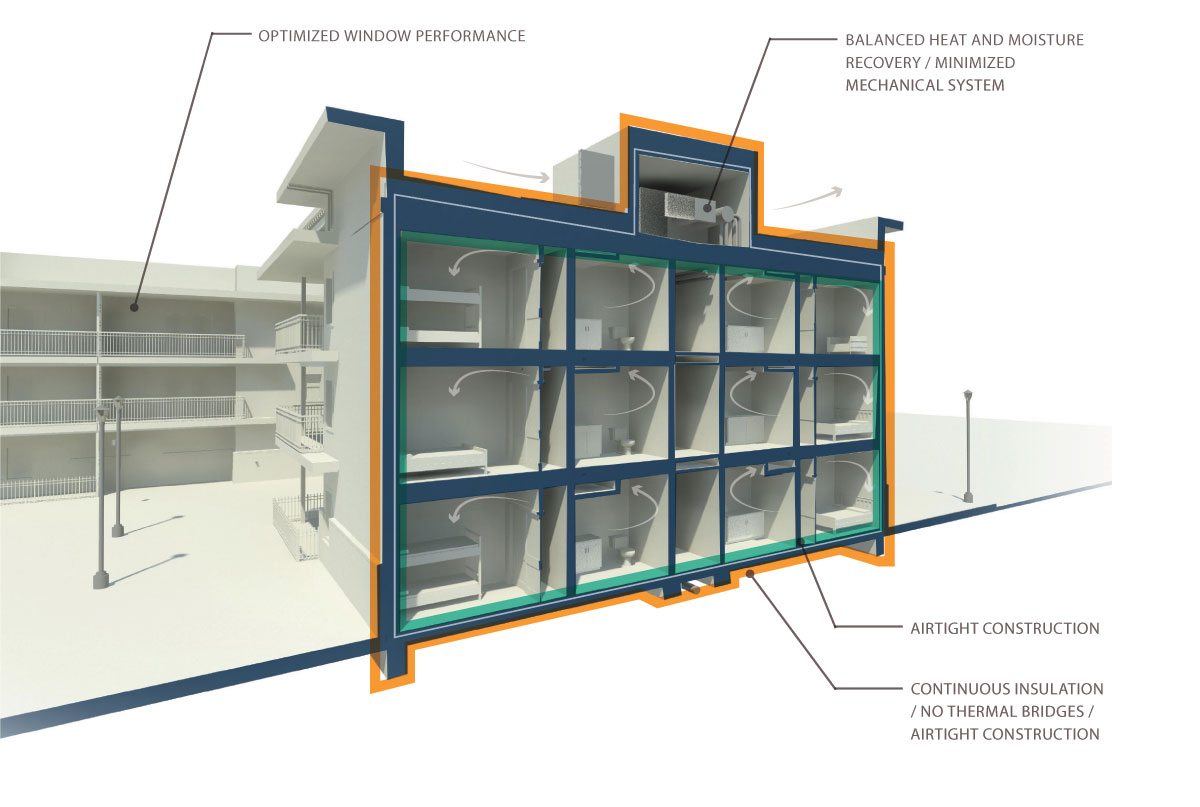

PASSIVE HOUSE DESIGN PRINCIPLES:

• Continuous Insulation / No Thermal Bridges

• Airtight Construction

• Optimized Window Performance

• Balanced Heat and Moisture Recovery

• Minimized Mechanical System

THE PASSIVE HOUSE DIFFERENCE:

• Reduces energy use 75-90%

• Comfortable and healthy:

– Airtight construction = no drafts, minimized temperature swings, reduced outdoor noise transmittance, reduced energy bills

–Constant mechanical ventilation = excellent indoor air quality

THE ANATOMY OF A PASSIVE HOUSE: DESIGN PRINCIPLES

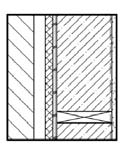

CONTINUOUS INSULATION / NO THERMAL BRIDGES

The envelope is a critical element in meeting Passive House standards. Improving assembly design to minimize heat loss through continuous insulation is important in assuring thermal comfort. Eliminating thermal bridging minimizes heat loss through the envelope, reducing condensation and building deterioration. Continuous insulation includes high R-value at the roof, walls, slabs, and even footings in some cases. Careful detailing at corners and junctions of assemblies is required to ensure that thermal bridging is eliminated to a satisfactory level.

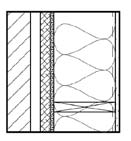

AIRTIGHT CONSTRUCTION

The Passive House standard has rigorous requirements for building airtightness. In order to achieve this, Passive House buildings have continuous airtight and wind tight barriers. These barriers cut down on heat loss and moisture migration due to infiltration. Design and construction teams must be prudent in maintaining the continuity of the air barriers during design, detailing, and construction.

OPTIMIZED WINDOW PERFORMANCE

Openings often present a weak point in the thermal performance of a building’s enclosure, but selection of high performance windows and doors with thermally broken frames is critical in minimizing losses and optimizing gains through a buildings envelope. Pairing selection with site- and climate-specific orientation and glazing strategies allows projects to optimize daylighting, solar gain, and summer shading.

BALANCED HEAT AND MOISTURE RECOVERY

The mechanical ventilation system and heat and moisture exchange are critical to the building’s thermal comfort, energy efficiency, and high quality indoor air. The stale air exhausted from the building warms filtered, fresh, incoming air, making use of otherwise wasted energy.

MINIMIZED MECHANICAL SYSTEM

Micro-load mechanical systems are possible in Passive House buildings because of the application of all of the design principles in an integrated envelope and systems design. The minimized systems provide thermal comfort through heating, cooling, and dehumidification.

ABOUT ORCHARDS AT ORENCO

Orchards at Orenco redefines the model for affordable living in the United States, blending deep green building technology with transit-oriented design to deliver a product that exceeds expectations.

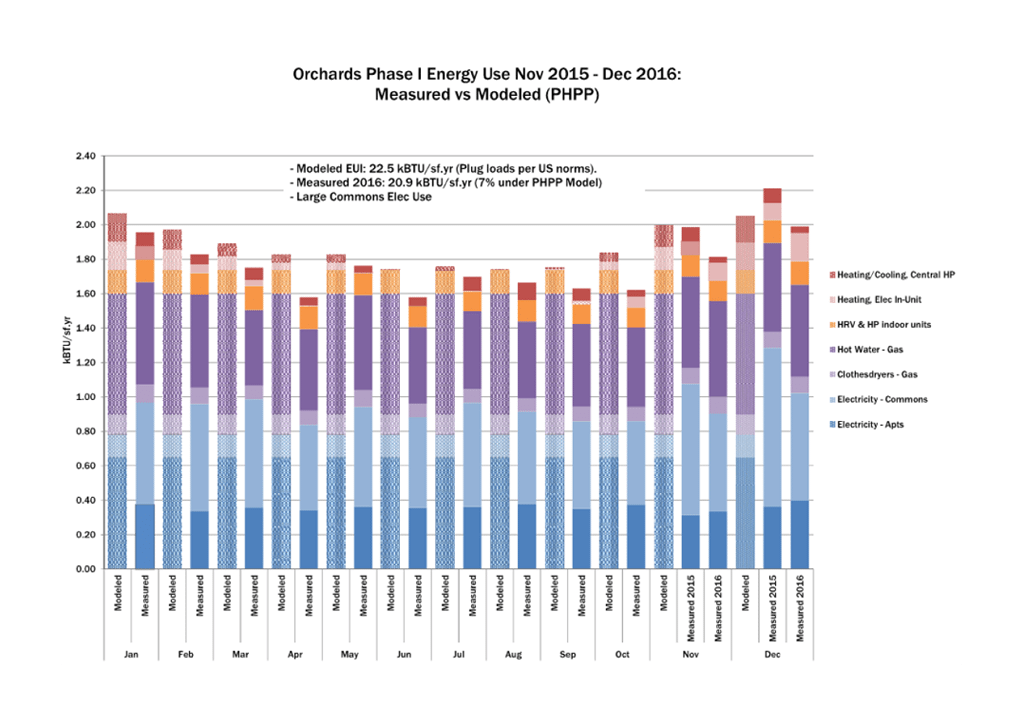

Phase I used forward-thinking strategies to become the largest multifamily project in North America built to the aggressive energy standards of the Passive House Institute US. Phase II is an example of implementing lessons learned from experience to apply the most cost-effective energy efficiency measures at standard construction cost while still achieving Passive House Certification under PHIUS+.

Advanced insulation strategies, meticulous attention to air barrier continuity, and innovative material use were paramount in attaining this extreme airtightness requirement. Energy-efficient features include an energy recovery ventilator and PVC-fiberglass hybrid, thermally-broken window frames with argon-filled triple pane glazing. Close collaboration between all partners in both project phases produced groundbreaking achievements that elevate building standards on a national level and enhances the quality of our own informed and enriched design.

INSPIRED TO CREATE AFFORDABLE LIVING

“We were really talking a lot about how do we go beyond just providing affordable rents and provide what we were calling affordable living. Meaning both affordable utilities, affordable rent, and the ability to have affordable transportation. Ankrom Moisan was great in the fact that they really understood what we were trying to achieve and also shared our goal in the mission of providing affordable housing—because we needed somebody who could do both—somebody who could do really innovative architecture, but also meet the objectives of our mission and provide affordable housing.”

– JESSICA WOODRUFF

Director of Housing Development, REACH

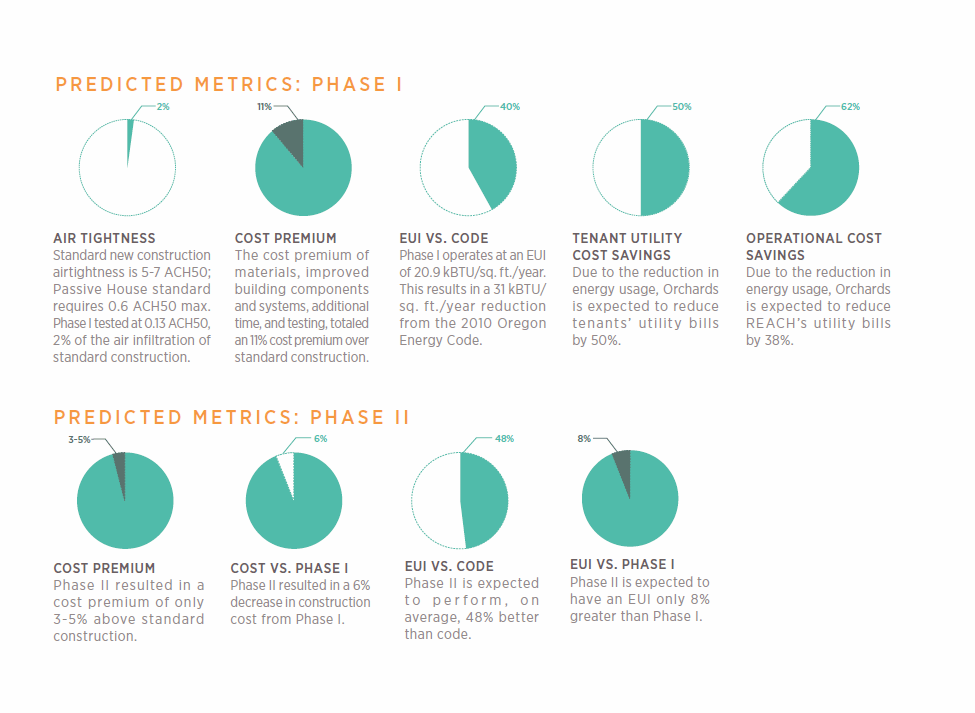

PHASE I: LEARNING

REACH set a goal in their 2010 Strategic Plan to have a Passive House project in their portfolio by 2015. Orchards at Orenco Phase I became that project. The cost premium associated with the innovative strategies applied in Phase I were entirely funded by significant private investment brought to the table by REACH.

FAST FACTS:

Completed: June 2015

Units: 57

Area: 57,750 sq. ft.

Construction: 3-story, wood-frame, concrete slab-on-grade foundation

Energy Performance: 31-71% better than code

Total cost premium to achieve Passive House: 11%

Total soft cost premium: 1.5%

Total hard cost premium: 9.5%

PHASE II: REFINING

Unlike Phase I, additional private resources were unavailable for Phase II, creating the need to reduce costs to meet strict budget limits. On Phase II we were able to take lessons learned and best practices from Phase I and build to PHIUS+ Certification standards at a negligible cost premium as compared to standard construction.

FAST FACTS:

Completed: July 2016

Units: 58

Area: 49,900 sq. ft.

Construction: 3-story, wood-frame, concrete slab-on-grade foundation

Energy Performance: 29-67% better than code

Total cost premium to achieve Passive House: NEGLIGIBLE

PHASE I: SYSTEMS & ASSEMBLIES COMPARISON

MAJOR ENVELOPE DIFFERENCES:

• Fully insulated slab & footings

• 2×10 walls with 1-1/2” exterior insulation

• Low-slope roof with R-81 insulation

SYSTEMS & DESIGN DIFFERENCES:

• Whole building ERV with heat pump

• Spaces outside conditioned envelope = very expensive doors and detailing

• Vertical envelope area: 35,000 sq. ft.

• Ultra airtight: 0.13 ACH50

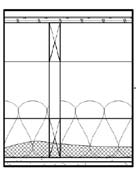

WALL

WALL

• Brick veneer or fiber cement siding

• 1-1/2” drainage cavity

• 1-1/2” mineral fiber insulation

• Mechanically fastened building wrap

• 1/2” plywood sheathing with taped seams (Air Barrier)

• Wood Studs (2X10)

• Blown-in Insulation (R-19)

• Vapor Retarder

• Gypsum Wallboard Type X

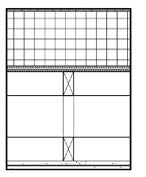

ROOF

• Fully Adhered TPO Roofing

• Coverboard

• 12” Rigid Insulation

• Plywood Sheathing taped at seams (Air Barrier)

• Roof Truss

• (2) Layers Gypsum Wallboard Type X

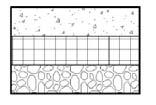

SLAB

SLAB

• Concrete Slab

• 4” EPS Insulation

• Under-slab Vapor Retarder

• Capillary Break

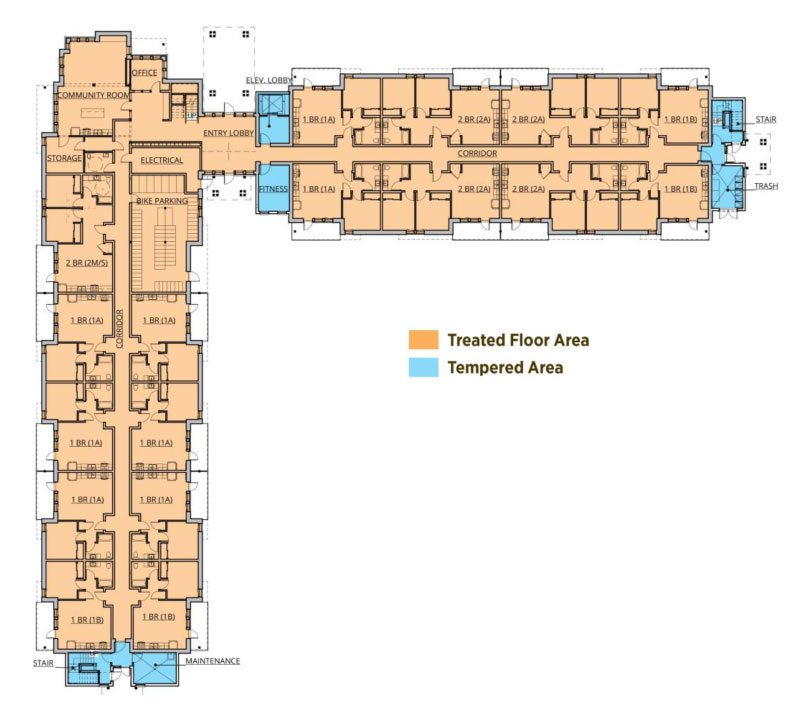

PHASE II: SYSTEMS & ASSEMBLIES COMPARISON

MAJOR ENVELOPE DIFFERENCES:

• Fully insulated slab, no insulation under footings

• 2×8 walls with 1” exterior insulation

• Steep-slope roof with R-60 insulation

• Vented attic

SYSTEMS & DESIGN DIFFERENCES:

• Same HVAC as Phase I, but with better zoning due to orientation

• All spaces inside conditioned envelope

• Reduced vertical envelope area: 27,700 sq. ft.

• Airtight: 0.42 ACH50

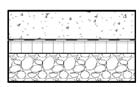

WALL

• Brick veneer or fiber cement siding

• Brick veneer or fiber cement siding

• 1-1/2” drainage cavity

• 1” mineral fiber insulation

• Mechanically fastened building wrap

• 1/2” plywood sheathing with taped seams (Air Barrier)

• Wood Studs (2X8)

• Blown-in Insulation (R-19)

• Vapor Retarder

• Gypsum Wallboard Type X

ROOF

• Asphalt Shingle Roof

• Asphalt Shingle Roof

• Roofing Under-layment

• Plywood Sheathing

• Roof Truss

• 1” Formed-in-Place Insulation

• R-80 Loose Fill Insulation

• Air/Vapor Barrier

• (2) Layers Gypsum Wallboard Type X

SLAB

• Concrete Slab

• Concrete Slab

• Under-slab Vapor Retarder

• 2” EPS Insulation

• Capillary Break

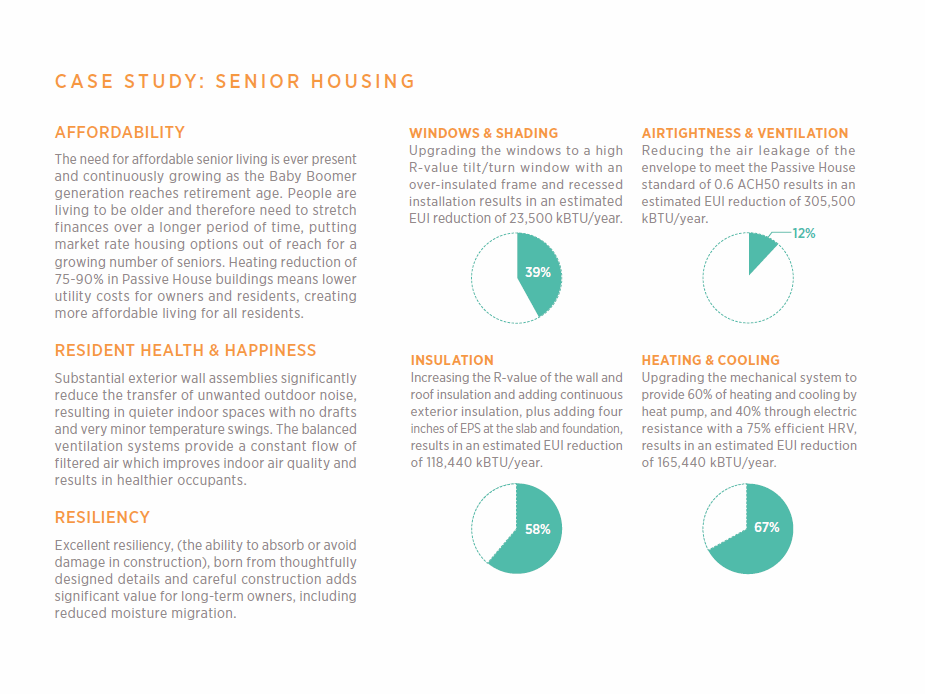

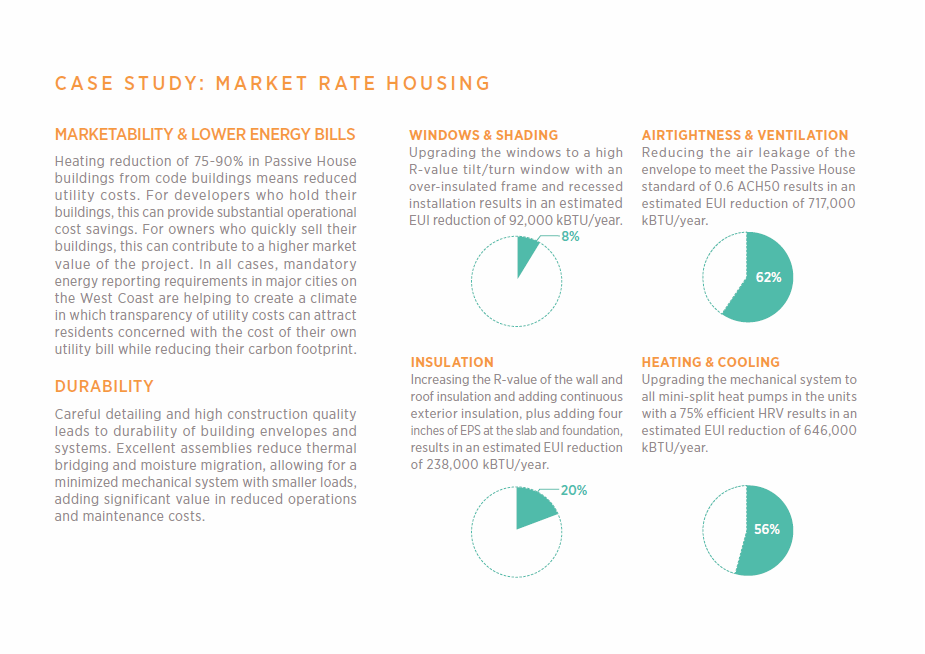

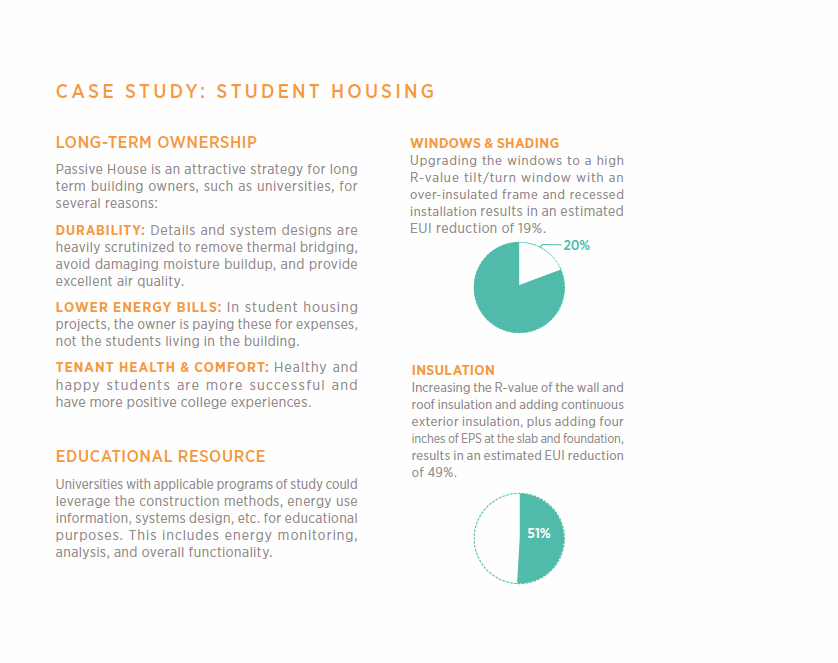

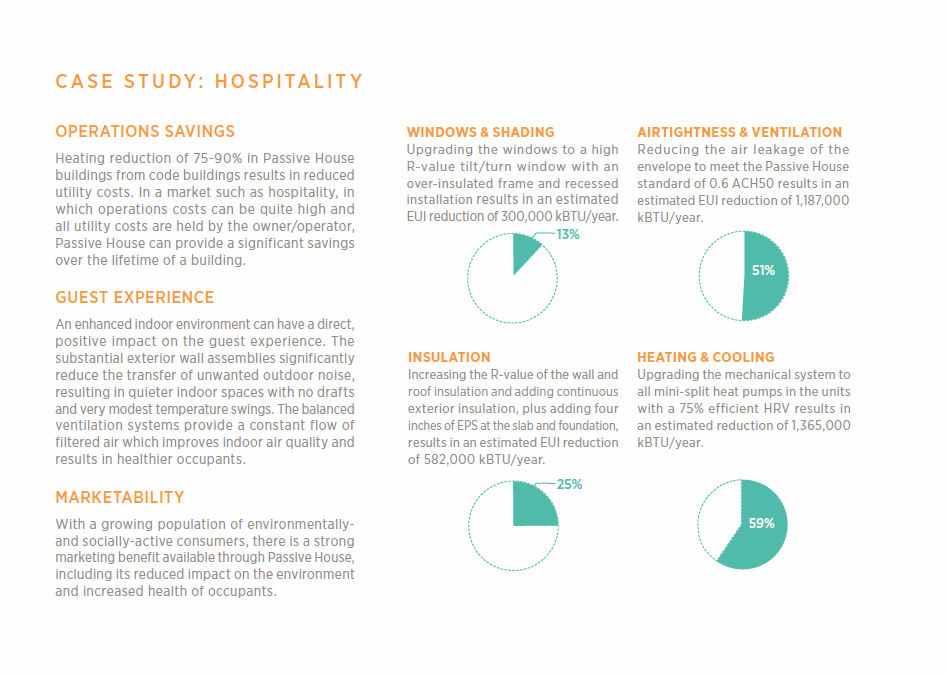

CASE STUDIES: INVESTIGATING PASSIVE HOUSE STRATEGIES FOR ADDITIONAL MARKETS

BACKGROUND

Case study projects currently in the design and construction phases were selected to analyze the use of cost-effective Passive House strategies in additional market sectors, including senior living communities, hospitality, market rate apartments, and student housing.

ECONOMY OF SCALE

All sectors studied are large, multifamily housing projects or hotels, providing an economy of scale that allows Passive House strategies to become more cost effective.

Through our experience applying lessons learned from Phase I to Phase II of Orchards at Orenco, we are able to determine the most cost-effective, energy efficient Passive House strategies that can be implemented at a larger scale to make Passive House construction possible at no cost premium. Paired with reduced operating cost for owners and residents, enhanced indoor comfort and health, and marketability opportunities, it is clear that large scale Passive House construction is bound to become widespread.

SELECTED AWARDS & PUBLICATIONS

• BEST OVERALL PROJECT OF THE YEAR

North American Passive House Conference 2015

• FIRST PLACE, AFFORDABLE HOUSING

North American Passive House Conference 2015

• BETTER BRICKS SUSTAINABLE PROJECT OF 2015

Portland Business Journal

• 2015 GOLDEN HAMMER AWARD, BEST OVERALL PROJECT

Oregon Opportunity Network

• 2015 BEST OF THE YEAR, MERIT WINNER, GREEN CATEGORY

Engineering News-Record

• NET ZERO ENERGY BUILDINGS, PASSIVE HOUSE + RENEWABLES

Passive House Institute, 2015

• PRESENTATION AT PHNW 2012 SPRING CONFERENCE