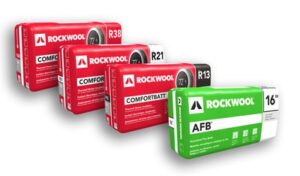

ROCKWOOL, North American stone wool manufacturer, has extended its Comfortbatt™ line with products available in several new R-values—R13/R21/R38, designed to provide customers with more options. In addition, ROCKWOOL has released AFB® for wood stud applications—an acoustical fire batt that is now available in new dimensions designed for wood stud cavities.

Comfortbatt® R13/R21/R38: Using Comfortbatt® within the building envelope can contribute to a robust thermal insulation solution that meets the variety of code requirements that exist across the United State,s the company says. Comfortbatt® is a semi-rigid stone wool batt insulation for exterior wood and steel stud applications in both new construction and renovations. ROCKWOOL now offers Comfortbatt® in R13/R15/R21/R23/R30/R38.

Comfortbatt® features a unique flexible edge designed to aid installation. Simply compress the flexible edge as the batt is inserted and release. The flexible edge is designed to spring back, expanding the batt against the stud cavity to give a complete fill. This flexibility ensures the expected R-value is achieved and maintained.

Comfortbatt® features a unique flexible edge designed to aid installation. Simply compress the flexible edge as the batt is inserted and release. The flexible edge is designed to spring back, expanding the batt against the stud cavity to give a complete fill. This flexibility ensures the expected R-value is achieved and maintained.

AFB® for wood stud applications is a lightweight, acoustical fire batt stone wool insulation specifically designed for wood stud interior wall and floor applications. The company states that its superior sound absorbency and fire protection contribute to the overall comfort and safety of occupants.

“In the US, codes and standards are constantly evolving,” says Garrett Feehrer, Marketing Manager USA at ROCKWOOL. “With our new ROCKWOOL Comfortbatt® range, ROCKWOOL now offers a solution for every climate zone and every application. Our customers are looking for products that make their jobs easier, and this extension of our existing Comfortbatt® line addresses that.

“In regard to AFB®, wood construction is certainly a growing trend in the built environment, and AFB® has been a trusted acoustical fire batt in steel stud applications for many years. We wanted to bring those same steel stud benefits to the new wood application market, this product allows us to do just that.”

Comfortbatt® and AFB® are non-combustible and resist temperatures up to 2,150˚F. The company states they provide excellent sound absorption due to their density and non-directional fiber structure and are uniquely durable against all forms of weather (vapor permeable, water repellent, high drying potential). ROCKWOOL stone wool products, including Comfortbatt® and AFB® are manufactured using sustainable materials, like basalt rock (an abundant natural resource) and recycled steel slag.

About ROCKWOOL

With five manufacturing facilities and over 1,000 employees, ROCKWOOL is North America’s largest stone wool producer, offering advanced building insulation, industrial and technical solutions.

At the ROCKWOOL Group, we are committed to enriching the lives of everyone who experiences our solutions. Our expertise is perfectly suited to tackling many of today’s biggest sustainability and development challenges, from energy consumption and noise pollution to fire resilience, water scarcity and flooding. Our range of products reflects the diversity of the world’s needs, supporting our stakeholders in reducing their own carbon footprint along the way.

Stone wool is a versatile material and forms the basis for all our businesses. With more than 11,700 passionate colleagues in 39 countries, we are the world leader in stone wool solutions, from building insulation to acoustic ceilings, external cladding systems to horticultural solutions, engineered fibers for industrial use to insulation for the process industry, marine and offshore. For more information, visit: www.rockwoolgroup.com (global site) or www.rockwool.com (North America).