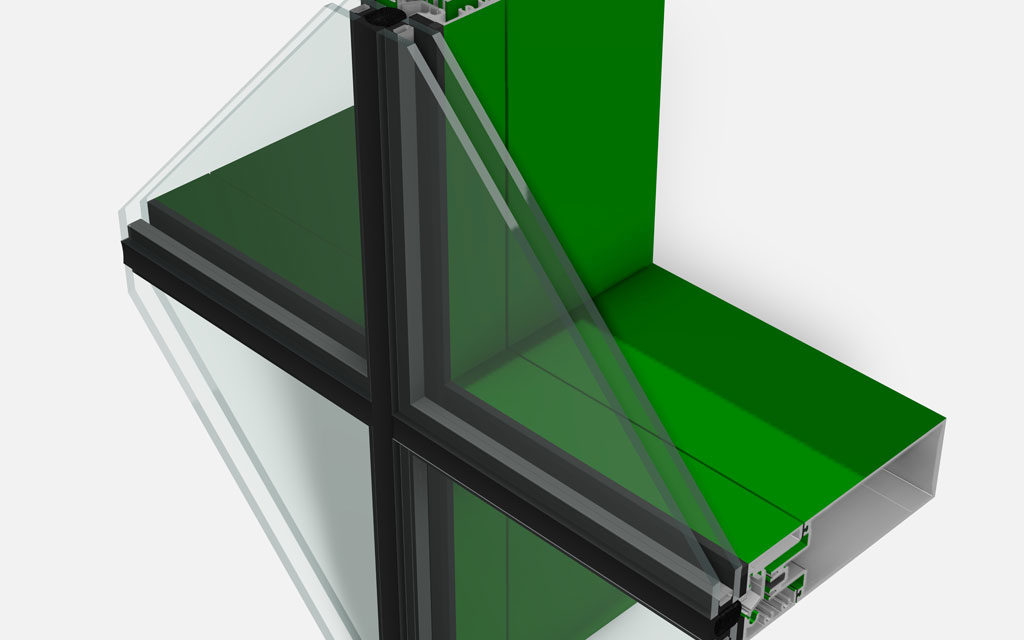

Walker, Michigan (Jan. 2019) – Tubelite Inc. launches a new 400 4-Side SSG Cassette Series glazing system for building envelopes in low- and mid-rise commercial curtainwall applications, such as retail centers, offices, health care facilities and schools. The aluminum-framed, factory-fabricated and factory-glazed system is field installed into the curtainwall grid with 2.5-inch interior sightlines and the strength of variable-depth back members in sizes from 5-5/8- to 10-inches.

This new cassette system allows for Tubelite’s proprietary glass-to-edge glazing, accommodating 0.25-inch-thick glass to triple-glazed units, without the need for captured perimeter members. It also features pivot-and-slide head and jamb anchors, and roll-over dead load sill anchors for fast and accurate installation.

This new cassette system allows for Tubelite’s proprietary glass-to-edge glazing, accommodating 0.25-inch-thick glass to triple-glazed units, without the need for captured perimeter members. It also features pivot-and-slide head and jamb anchors, and roll-over dead load sill anchors for fast and accurate installation.

“No other manufacturer offers this concept and a U.S. patent is pending approval on a number of our unique Cassette Series features,” said Tim Fookes, Tubelite’s vice president of engineering. “This new system uses reliable screw spline construction and is designed for use with our time-tested 400 Series Curtainwall framing.”

In addition to its 400CW, 400T, 400SS and 400TU curtainwall, Tubelite’s Cassette Series is compatible with its MaxBlock® sun shades and its door frames. It also can be modified to attach to other systems for retrofit applications.

Fookes added, “Our innovative Cassette Series, its efficient integration with other systems and its dependable performance contribute to a complete, convenient installation. When contractors can save time in the field and make the best use of their available labor, by applying the four-side structural silicone seal under factory-controlled conditions, it helps the project team stay on schedule and within budget, as well as meet projects’ performance, sustainability and aesthetic goals.”

Tubelite’s 400 4-Side SSG Cassette Series has passed testing for air and water infiltration, structural integrity, condensation resistance and thermal performance. The aluminum used to produce all of Tubelite’s framing systems, sun shades and light shelves can be extruded using EcoLuminum™, a high recycled-content aluminum billet composition. Anodized and painted finishes in a broad range of colors can be specified for Tubelite’s Cassette Series’ aluminum framing, snap-on perimeter closures, and optional horizontal and vertical accent covers. Durable finishes reduce buildings’ maintenance costs and enhance long lifecycles.

Please visit www.tubeliteinc.com, to learn more about Tubelite’s new 400 4-Side SSG Cassette Series product design details, test reports, installation instruction and specific performance data. For additional information or personalized assistance in selecting aluminum fenestration products, please email dependable@tubeliteinc.com or call 800-866-2227.

About Tubelite Inc.

For more than 70 years, glazing contractors have counted on Tubelite’s dependable service, fabrication and distribution of architectural aluminum products. Part of Apogee Enterprises, Inc., the company is an industry leader in eco-efficient storefront, curtainwall and entrance systems, and recognized for its fast, reliable and consistent delivery.

Tubelite’s corporate office, fabrication, warehouse and shipping operations are located in Walker, Michigan. Its Dallas location provides additional fabrication, warehouse and shipping operations. Its facility in Reed City, Michigan, houses the company’s aluminum extrusion operation. The company also has offices in Rock Hill, South Carolina, and Warwick, Rhode Island.

Tubelite and its staff are members of the American Architectural Manufacturers Association (AAMA), the American Institute of Architects (AIA), the Construction Specifications Institute (CSI), the National Fenestration Rating Council (NFRC), the National Glass Association/Glass Association of North America (NGA/GANA), the Society of Military Engineers (SAME) and the U.S. Green Building Council (USGBC).