Around the world, people are recognizing a growing need for microbial control in paints and coatings used in public buildings. Microbes or microorganisms are living cells that are only able to be detected by the naked eye once they have multiplied to the millions. Types of microorganisms include bacteria, algae, fungi and mold.

The need for microbial control stems from the fact that there are an estimated 4.5 million bacterial and fungal species throughout the planet, many of which travel and migrate via the constant ebb and flow of human foot traffic through an ever-changing population of people visiting public buildings. Under the right conditions, some microbes can double in number every 30 minutes or faster.

Office buildings, hotels, schools and universities, retail establishments, hospitals, apartment buildings and senior living facilities include a myriad of fixed, painted or coated surfaces on which microorganisms may survive. Examples include:

-

- Interior, aluminum handrails in government buildings

- Patient room and intensive care units, entrances of hospitals and medical facilities

- Classroom window frame surfaces in schools and universities

- Entranceways of retail stores and shopping malls

- Column covers in hotels

- Light shelves in office buildings

- Interior frames of window units for historic renovations

Most surfaces within public buildings should be cleaned on a regular basis to help prevent the growth of bacteria, mold and mildew that can cause stains and odors on the surface of a product. However, cleaning alone may not remove the microbes. Usually not seen until they are concentrated on a surface, microbes multiply, break down these surfaces and paints, and cause a loss of coating or paint integrity. This growth is perceived as a stain and will continue to expand, using the surface itself as a food source and releasing unpleasant odors, until the microbial population is removed.

Photo courtesy of BE&K; Wausau Window and Wall Systems

To augment cleaning programs, coating technologies containing antimicrobial compounds have been developed to provide an additional level of protection for the coating. Antimicrobial compounds can help prevent growth of stain- and odor-causing bacteria to help maintain the paint or coating integrity. These coatings may be used on a wide range of products in high-traffic public buildings including door knobs, faucet handles, bedrails in hospital and senior living facilities, and window frames.

This article describes the development of antimicrobial compounds and their use in product finishes and coatings; how they are tested to prove effectiveness at protecting the paint or coating; and the advantages these coatings provide to owners and operators of public buildings, and the people who use, work and live in them.

Photo courtesy of Linetec

Types of Microbes

Bacteria

Billions of years ago, bacteria – single-celled organisms – were among the earliest forms of life on Earth. Bacteria are microscopic, single-cell organisms that are divided into two main groups by virtue of cell wall constitution – Gram-positive, such as Staphylococcus, MRSA and Gram-negative, such as E. coli, Pseudomonas and Salmonella.

There is no escaping the presence of bacteria; in fact, the majority of the bacteria encountered are beneficial to the environment by helping return nutrients to the soil through decomposition of organic waste, or beneficial even to the human body (probiotics) through the digestion of food. However, some bacteria cause stains, odors and product surface deterioration as their metabolisms produce acidic materials and sulfur-based compounds. These bacteria can adversely affect the everyday surfaces.

Microbes or microorganisms are living cells that are only able to be detected by the naked eye once they have multiplied to the millions. Types of microorganisms include bacteria, algae, fungi and mold. Credit: Getty Images/iStockphoto

Most bacterial test protocols require the testing of two organisms, one Gram-positive and the other Gram-negative due to the differences in the cell wall structure. Some antimicrobials are more effective against one or the other of these groups. Others are broad spectrum with good efficacy measured against both.

Fungus

Early fossil records suggest that fungi have been on Earth for more than 550 million years; some experts estimate that today more than 1.5 million fungus species exist. Common fungi include mushrooms, puffballs, truffles, yeasts and most mildews.

Unlike bacteria, fungi are multi-cellular organisms that contain membrane-bound organelles, and a “true nucleus.” Fungal cells are encompassed by a strong, but flexible, nitrogen-containing polysaccharide called “chitin.” The chitin protects the fungus and, depending on the mode of action, can reduce or eliminate the effectiveness of many antimicrobials.

The most common means of fungal reproduction is by the formation of spores. This occurs in fungi such as Aspergillus niger (black shower mold), Penicillium pinophilum (bread mold) and Trichophyton mentagrophytes (Athlete’s Foot).

Mold spores are present everywhere in both indoor and outdoor environments, and many of the products found in buildings provide rich nutrient sources. The most common defense is prevention: control moisture in the building to avoid high humidity levels and look for products with antimicrobial protection to resist the growth of mold.

How Does an Antimicrobial Work?

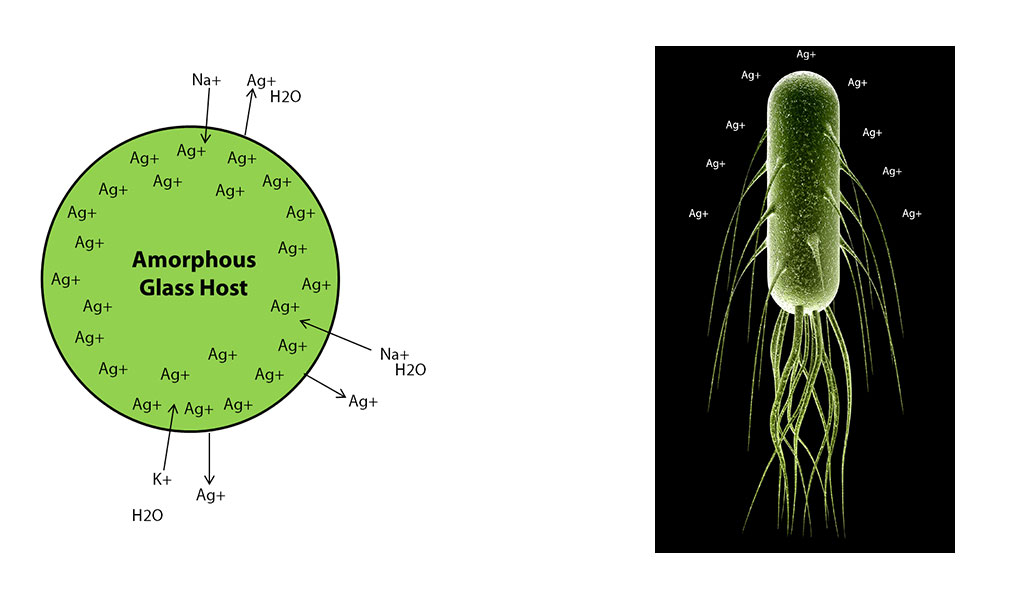

An antimicrobial agent in a coating is designed to inhibit the growth of odor-causing bacteria and help prevent product deterioration of the coating from mold and mildew. It does not replace normal cleaning practices nor is it intended to protect users from disease-causing microorganisms. Microbes that land on surfaces treated with antimicrobial coatings are not killed; rather, the silver-based particles emit ions that interfere with the microorganism’s metabolism, reducing its ability to reproduce.

Coupled with regularly scheduled cleanings, antimicrobial-based coatings create an inhospitable environment for microbial growth by damaging the microbes’ cell walls. In addition, this interferes with the conversion of nutrients into energy, inhibiting reproduction. The microbes die off and are not replaced within the population.

Antimicrobial treatments in solid products are largely surface treatment effects. For most, efficacy is related to controlled diffusion at the surface. Limited or no migration out of the surface provides durability as the incorporated active ingredient is not used up. The benefits of antimicrobial coatings on surfaces include odor control, reduced staining and surface discoloration from bacteria, mold and mildew. However, products and surfaces that have been treated with antimicrobial coatings do not disinfect their surroundings or contents. For example, the water in a treated cup is not sterilized, nor is growth in the water inhibited.

Three-Coat Finishing Process Meets Most Stringent Specification

An antimicrobial coating technology can provide an added level of protection for the coated surface. Through research and testing, a proprietary, high-performance architectural coating system with antimicrobial protection has been developed to coat interior and exterior aluminum surface architectural products to inhibit the growth of stain- and odor-causing bacteria. This architectural liquid coating is based on a 70% PVDF resin-based system.

When moisture is present, the antimicrobial technology in the coating activates the ion exchange mechanism and small amounts of silver cations (positively charged ions) are released into aqueous environments. The release rate is highly regulated by the unique amorphous glass structure giving extraordinary longevity. The released silver acts on odor-causing bacteria by disrupting metabolism and reproduction.

This architectural coating with antimicrobial technology consists of a three-coat finishing process designed to meet the requirements of AAMA 2605-20, “Voluntary Specification, Performance Requirements and Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels.” This is the most stringent, high-performance specification standard for architectural coatings published by the Fenestration and Glazing Industry Alliance.

The architectural coating’s antimicrobial protection safeguards the finished aluminum product’s surface throughout its useful lifetime. Incorporated during the coating’s manufacturing process, the antimicrobial additives operate on the cellular level to continuously disrupt and prevent uncontrolled growth of the microorganism.

Where’s the Proof?

The antimicrobial technology helps to prevent the growth of stain- and odor-causing bacteria on the coating itself, while the coating protects the substrate. As microbes come into contact with the coating, the antimicrobial agent in the coating penetrates the microorganism’s cell wall, disrupting its ability to grow and reproduce. The enhanced coating does not replace traditional cleaning methods, but works to keep the surface cleaner longer by inhibiting microbial growth.

The proprietary antimicrobial technologies used in these architectural coating products are registered and approved by the U.S. Environmental Protection Agency (EPA) for their specific use in the product in which they are incorporated. They have a history of safe use in consumer, industrial and medical product applications around the world. All applications must follow guidelines set by the EPA, including the language used to market products with antimicrobial protection. The EPA regulates built-in antimicrobial claims under the Federal Insecticide, Fungicide and Rodenticide Act, which limits claims to protection of the treated product and prohibits public health claims.

How Is It Tested?

Surfaces labeled to be antimicrobial to resist odors and stains that can adversely affect the coating must be effective against multiple bacterial species as confirmed by approved test methodologies. There are international standard-setting bodies that are responsible for producing and validating antimicrobial test methodologies that are unbiased and provide an accurate representation of the efficacy against bacterial species.

Surfaces labeled to be antimicrobial to resist odors and stains that can adversely affect the coating must be effective against multiple bacterial species as confirmed by approved test methodologies. There are international standard-setting bodies that are responsible for producing and validating antimicrobial test methodologies that are unbiased and provide an accurate representation of the efficacy against bacterial species.

These standard-setting bodies include the International Standards Organization (ISO), American Society for Testing and Material (ASTM), and Japanese Industrial Society (JIS). The most common methodologies are the ISO 22196, JIS Z 2801 and ASTM E2180; a comparison of these methods can be found in the following table.

| ISO 22196 | JIS Z 2801 | ASTM E 2180 | |

| Bacteria | Staphylococcus aureus Escherichia coli | Staphylococcus aureus | Escherichia coli |

| Carrier | Low nutritive, aqueous | Low nutritive, aqueous | Non-nutritive viscous carrier |

| Comparison to controls | Must have unprotected control samples | Must have unprotected control samples | Must have unprotected control samples |

Testing of antimicrobial treated hard surfaces is similar, regardless of the standard-setting body. Testing is conducted by placing organisms onto the protected surface and in parallel on an unprotected surface. The samples are incubated for a specified amount of time at an optimal temperature for bacterial growth. After the incubation, microbiologists remove the organisms and count them. The amount of bacteria remaining on the unprotected surface is compared with that on the protected surface resulting in a percent reduction or a log reduction. Because the bacteria are counted, this quantitative test is the “gold standard” of antimicrobial testing to determine if the product is effective at resisting the growth on the coating of mold, stains and odor-causing bacteria.

In addition to quantitative testing, samples also can be tested using qualitative test methods. These methods are visually assessed for bacterial inhibition. If bacteria grow to the edge of a sample, the underlying substrate becomes opaque. If a sample is sufficiently protected, there will be a clear zone around the sample where bacteria cannot grow; this is referred to as a zone of inhibition. The type of test utilized for a specific antimicrobial compound will depend on the antimicrobial being utilized and the matrix being treated.

These are all relatively complicated and involved test procedures and, for this reason, it is suggested that a well-accredited microbiology laboratory, that tests coatings and maintains alignment with developmental bodies (ISO, ASTM, AATCC), be employed. Additionally, laboratories can be accredited by ISO to ensure that there is no variation from accepted methodologies.

How Is It Specified?

Recognizing the need for high-performance coatings with antimicrobial protection for use in public buildings to help prevent the growth of stain- and odor-causing bacteria, mold and mildew, specifiers, owners and architects can realize the benefit of these antimicrobial architectural coatings by including specification language such as:

PVDF-based, AAMA 2605-20, fluoropolymer finish containing minimum 70% PVDF resin, three-coat system with Microban® antimicrobial protection, [paint code].

What Are the Additional Considerations?

Photo courtesy of Linetec

Based on AAMA 2605 specification standard, 70% PVDF resin-based architectural coatings for high-performance applications maintain their exceptional durability, even with the addition of the antimicrobial agent. AAMA 2605 includes a 10-year South Florida exposure test in which the coating must lose no more than 5ΔEs of color. Per the specification, the finish must retain a minimum of 50% of the original gloss value.

The antimicrobial product protection offered by these high-performance coatings is available in nearly any color option including mica and metallic coatings. Some coatings manufacturers may limit certain bright colors that could fall short of AAMA 2605’s requirements. Finishing applicators can provide guidelines regarding color selection and material sizes, as well as samples, estimates and warranties.

Choosing a finishing applicator that has experience working with PVDF resin-based coatings and antimicrobial technology will ensure the intended appearance and performance is achieved on architectural aluminum products.

Please remember, normal cleaning practices of the finished aluminum products must be maintained. This coating is not designed to replace normal cleaning practices. The proprietary antimicrobial protection that is built into these high-performance architectural coatings during their manufacturing process works continuously for the useful lifetime of the coating.

About the author

Tammy Schroeder, LEED® Green Associate, serves as marketing manager at Linetec, a single source solution and the nation’s largest independent architectural metals finishing company. With 20 years of experience in the finishing industry, she shares her knowledge of liquid paint coatings, powder coat and anodize with architects, specifiers and architectural product manufacturers in commercial and residential markets. She can be reached at tammy.schroeder@linetec.com or by calling 800-236-2589.

Tammy Schroeder, LEED® Green Associate, serves as marketing manager at Linetec, a single source solution and the nation’s largest independent architectural metals finishing company. With 20 years of experience in the finishing industry, she shares her knowledge of liquid paint coatings, powder coat and anodize with architects, specifiers and architectural product manufacturers in commercial and residential markets. She can be reached at tammy.schroeder@linetec.com or by calling 800-236-2589.

Read more articles by Tammy Schroeder:

“Finishing innovations, options and trends for architectural aluminum products“

“High-performance architectural coatings for extruded aluminum”

“Architectural color trends: conceptual inspiration to practical application“